Introduction.

The E-OLSS (Electronic – Open centre Load Sensing System) is an energy saving system to reduce fuel consumption by means of controlling the swash plate angle.

A Variable-displacement swash plate piston pump is used with an OLSS control valve. For this combination to work there is a series of valves mounted on the pump to sense the different machine operating demands

The E-OLSS (Electronic – Open centre Load Sensing System) is an energy saving system to reduce fuel consumption by means of controlling the swash plate angle.

A Variable-displacement swash plate piston pump is used with an OLSS control valve. For this combination to work there is a series of valves mounted on the pump to sense the different machine operating demands

Effective Use of Engine Horsepower

For optimum out-put of the machine its important for the engine to maintain a set speed.

As the load in the hydraulic system changes the discharge amount from the pump needs to

be adjusted.

The valves mounted on the hydraulic pump that sense the change in working conditions.

1.Servo Valve.

2.CO valve (Cut-Off control)

3.NC valve (Neutral control).

4.TVC valve (Torque Variable Control)

All the pump control valves and servo piston are operated by charge pump pressure.

For optimum out-put of the machine its important for the engine to maintain a set speed.

As the load in the hydraulic system changes the discharge amount from the pump needs to

be adjusted.

The valves mounted on the hydraulic pump that sense the change in working conditions.

1.Servo Valve.

2.CO valve (Cut-Off control)

3.NC valve (Neutral control).

4.TVC valve (Torque Variable Control)

All the pump control valves and servo piston are operated by charge pump pressure.

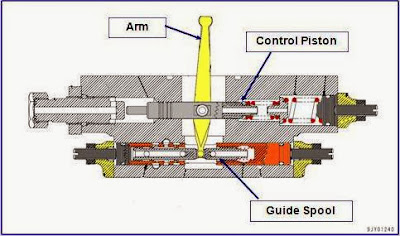

Servo Valve.

The Servo Valves controls the pump out-put from the signals received fromTVC, CO and NC

valves.

The Servo Valves controls the pump out-put from the signals received fromTVC, CO and NC

valves.

The

arm is connected into the servo piston and senses the servo piston position,

this will

allow the pump to discharge the volume amount corresponding to signal pressure.

allow the pump to discharge the volume amount corresponding to signal pressure.

Posted by Unknown

Posted by Unknown

Friday, December 27, 2013

Friday, December 27, 2013