Hydraulic systems are widely used in agriculture, construction and

manufacturing industry. Bulldozers, cranes, tractors, elevators and all

such heavy machines use hydraulics. Hydraulic hybrid vehicles are some

of the newest developments in this field of technology. Hydraulics is an

applied science, which exploits the mechanical properties of fluids to

build hydraulic systems that can perform heavy duty mechanical jobs with

precision. Hydraulic systems offer power with precise control and

versatility. At the core of every hydraulic system is the hydraulic

cylinder. It is the central component on which all hydraulic systems are

dependent. Therefore, one must learn rebuilding these cylinders, as it

saves money and valuable time.

Construction and Working

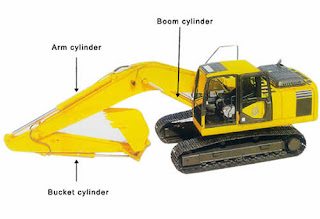

Any hydraulic system is made of two parts; the hydraulic pump that generates the pressure and the hydraulic cylinder that delivers the mechanical action in response to pressure. The cylinder is a barrel fitted with a piston, which fluidly moves back and forth. The cylinder barrel is of course sealed from both ends.

The piston divides the barrel body into two parts; the rod end, which is the side from where piston enters the barrel body and the other side, which is capped, called the cap end. The piston is driven back and forth, by the hydraulic fluid, which is mostly oil, introduced by the hydraulic pump. The piston has sliding rings and seals, which prevent the leakage of fluid from one part of the piston compartment, to the other part. The piston is connected with appropriate mounting arrangement. It conveys piston motion to appropriate moving part of the machine, which carries the load.

The idea behind every hydraulic system working is simple. The pressure applied at one point is conveyed to other point by the use of an incompressible fluid which is usually oil. So when the pump pushes oil into the piston chamber, from the cap side, the piston is lifted up. When oil is sucked back by the hydraulic pump from the chamber, the piston gets pushed down. This is how a hydraulic system works by conveying force through an incompressible fluid. By using pistons of different surface areas, force multiplication can be achieved. A heavier load can be lifted up by relatively lesser force, using this principle!

Repair Tips

Here are some common problems that can break a cylinder or cause its malfunctioning. I will outline the possible solutions that can help you rebuild or repair your cylinder. Read instruction manuals for the machine supplied by the manufacturers carefully, before going ahead.

Problem 1: The cylinder is cracked or piston rod is bent

Solution: If on observation, you see the cylinder rod is bent or the cylinder barrel is cracked, there is pretty much nothing you can do. It's time to replace the cylinder. Forging a new barrel or straightening the piston rod is beyond your capacity. So if this is the case, repairing the cylinder is not possible. In such a case, only a specialized repair shop can rebuild the cylinder for you, as a customized new shaft may need to be forged and the cylinder bore may need to be honed.

Problem 2: The seal is broken

Solution: If the shaft seal is broken, the pressurizing fluid leaks and loses pressure, impairing working of the cylinder. It can be replaced. However, an opening of the entire cylinder assembly is necessary. Let us see how we can go about it. Obtain a diagram of the cylinder if possible, as it will help you in reassembly. These diagrams can be had from the equipment manufacturers and you can also carry a printout. You can order a standard repair kit for your cylinder which is supplied by the manufacturing company. It includes spare cylinders, spare seals, O-rings and other spare parts according to the number and type of cylinders in your machine.

The assembly of the cylinder varies with machine type. Locate the seal position first. Mostly, you will find it around the shaft on one end. The shaft entry end can be accessed by unscrewing the lid from that side. You may need to unscrew the bolts, to remove the cover. Then loosen the pipes or valves that transmit the hydraulic fluid into the chambers which will release pressure. This will enable you to remove the shaft which otherwise cannot be removed due to hydraulic pressure. Handle the shaft carefully and take care that you do not scratch it. Detach the piston from the shaft and replace the seal with the spare one from the repair kit. Make sure that the seal is aligned rightly. Oil all parts after fitting and reassemble everything in exactly reverse order.

Problem 3: Piston Rings are damaged

Solution:If the piston rings are damaged, then they can be replaced too, by the same disassembling procedure, as for the above problem. The piston rings need to be removed and replaced very carefully. Oil the rings and cylinder assembly, before putting back everything together.

If you have a multiple cylinder arrangement, things are more complicated. It is better to consult a qualified technician before going ahead. Always remember one rule, while you are solving mechanical problems, do not proceed without a reason to take a particular action. Also, study the assembly and causative framework of the machine before going for repair. This repair can be a good learning experience for anyone who loves machine design.

Construction and Working

Any hydraulic system is made of two parts; the hydraulic pump that generates the pressure and the hydraulic cylinder that delivers the mechanical action in response to pressure. The cylinder is a barrel fitted with a piston, which fluidly moves back and forth. The cylinder barrel is of course sealed from both ends.

The piston divides the barrel body into two parts; the rod end, which is the side from where piston enters the barrel body and the other side, which is capped, called the cap end. The piston is driven back and forth, by the hydraulic fluid, which is mostly oil, introduced by the hydraulic pump. The piston has sliding rings and seals, which prevent the leakage of fluid from one part of the piston compartment, to the other part. The piston is connected with appropriate mounting arrangement. It conveys piston motion to appropriate moving part of the machine, which carries the load.

The idea behind every hydraulic system working is simple. The pressure applied at one point is conveyed to other point by the use of an incompressible fluid which is usually oil. So when the pump pushes oil into the piston chamber, from the cap side, the piston is lifted up. When oil is sucked back by the hydraulic pump from the chamber, the piston gets pushed down. This is how a hydraulic system works by conveying force through an incompressible fluid. By using pistons of different surface areas, force multiplication can be achieved. A heavier load can be lifted up by relatively lesser force, using this principle!

Repair Tips

Here are some common problems that can break a cylinder or cause its malfunctioning. I will outline the possible solutions that can help you rebuild or repair your cylinder. Read instruction manuals for the machine supplied by the manufacturers carefully, before going ahead.

Problem 1: The cylinder is cracked or piston rod is bent

Solution: If on observation, you see the cylinder rod is bent or the cylinder barrel is cracked, there is pretty much nothing you can do. It's time to replace the cylinder. Forging a new barrel or straightening the piston rod is beyond your capacity. So if this is the case, repairing the cylinder is not possible. In such a case, only a specialized repair shop can rebuild the cylinder for you, as a customized new shaft may need to be forged and the cylinder bore may need to be honed.

Problem 2: The seal is broken

Solution: If the shaft seal is broken, the pressurizing fluid leaks and loses pressure, impairing working of the cylinder. It can be replaced. However, an opening of the entire cylinder assembly is necessary. Let us see how we can go about it. Obtain a diagram of the cylinder if possible, as it will help you in reassembly. These diagrams can be had from the equipment manufacturers and you can also carry a printout. You can order a standard repair kit for your cylinder which is supplied by the manufacturing company. It includes spare cylinders, spare seals, O-rings and other spare parts according to the number and type of cylinders in your machine.

The assembly of the cylinder varies with machine type. Locate the seal position first. Mostly, you will find it around the shaft on one end. The shaft entry end can be accessed by unscrewing the lid from that side. You may need to unscrew the bolts, to remove the cover. Then loosen the pipes or valves that transmit the hydraulic fluid into the chambers which will release pressure. This will enable you to remove the shaft which otherwise cannot be removed due to hydraulic pressure. Handle the shaft carefully and take care that you do not scratch it. Detach the piston from the shaft and replace the seal with the spare one from the repair kit. Make sure that the seal is aligned rightly. Oil all parts after fitting and reassemble everything in exactly reverse order.

Problem 3: Piston Rings are damaged

Solution:If the piston rings are damaged, then they can be replaced too, by the same disassembling procedure, as for the above problem. The piston rings need to be removed and replaced very carefully. Oil the rings and cylinder assembly, before putting back everything together.

If you have a multiple cylinder arrangement, things are more complicated. It is better to consult a qualified technician before going ahead. Always remember one rule, while you are solving mechanical problems, do not proceed without a reason to take a particular action. Also, study the assembly and causative framework of the machine before going for repair. This repair can be a good learning experience for anyone who loves machine design.

THANKS FOR VISITING RELATIVES

Title Post: Rebuild a Hydraulic Cylinder

Rating: 100% based on 99998 ratings. 5 user reviews.

Author: Unknown

I hope this article was helpful for you. If you want to quote, either part or all of the contents of this article please include a dofollow link https://engineering-toplus.blogspot.com/2013/12/rebuild-hydraulic-cylinder.html. Thanks already stopped reading this article

Title Post: Rebuild a Hydraulic Cylinder

Rating: 100% based on 99998 ratings. 5 user reviews.

Author: Unknown

I hope this article was helpful for you. If you want to quote, either part or all of the contents of this article please include a dofollow link https://engineering-toplus.blogspot.com/2013/12/rebuild-hydraulic-cylinder.html. Thanks already stopped reading this article

Posted by Unknown

Posted by Unknown

Saturday, December 28, 2013

Saturday, December 28, 2013

Posted in:

Posted in:

3 comments:

I enjoyed reading this blog! Thanks for describe about Hydraulic Cylinders. Great blog indeed!

Hydraulic Cylinders For Sale

Hydraulic Cylinder and Hydraulic Compact Power Pack Manufacturers are one of the prime product and is manufactured and supplied by Dynamic Hydrofab through out India. We have outlined these cylinders in such a way, that these are not difficult to utilize, and the maintenance expense is too low. With years of involvement in this area, now we are enough capable of making an extensive variety of incredible designs of Hydraulic Cylinders which are powered by hydraulic pressures. Most of these Hydraulic Cylinders are used within different commercial enterprises to perform heavy duty work with exactness. Now we have become one of the Top Hydraulic Cylinder Manufacturers in India. Visit Hydraulic Cylinders Manufacturers India or Hydraulic Compact Power Packs to know more about us. You can mail us at: dhf@dhf.in, dhfdelhi@gmail.com or you can call us at: +91-99100 00424.

Nice post! thanks for the useful information

hydraulic hose repair

Post a Comment